Phenix introduces the groundbreaking 7.0mil Chameleon Black Red Paint Protection Film, a cutting-edge solution designed to safeguard your car’s surface from the everyday hazards of the road. With this exceptional product, you can enjoy peace of mind, knowing that your car’s exterior is shielded against the elements, preserving its showroom finish for years to come.

Crafted with meticulous attention to detail, our 7.0mil Chameleon Black Red Paint Protection Film offers unmatched quality and performance. Its unique Chameleon Black Red finish adds an elegant touch as it envelops your vehicle’s body, fitting seamlessly like a second skin. This film imparts a distinctive, understated appearance to your vehicle, enhancing its allure without any reflective sheen, making it stand out on the road.

Our PPF not only enhances the aesthetic appeal but also delivers exceptional protection against scratches, stone chips, road debris, and chemical contaminants, especially in vulnerable areas such as bumpers, hoods, and doors. Additionally, it guards your vehicle against the sun’s harmful UV rays, preventing the original paint job from fading. The film is designed to resist yellowing, ensuring that your vehicle maintains its sleek appearance even under the harshest sunlight.

Constructed from TPU material, which is renowned as the gold standard for paint protection, our film offers remarkable durability and flexibility. The high-quality acrylic adhesive, protected by the PET release liner, ensures a smooth and trouble-free installation process. It effortlessly conforms to the complex curves and contours of your vehicle, providing seamless coverage and an invisible shield against abrasive debris. Moreover, the 7.0mil thickness adds an extra layer of robust protection, significantly reducing the risk of surface damage from everyday encounters.

Experience long-lasting performance with our 7.0mil Chameleon Black Red Paint Protection Film, thanks to its state-of-the-art heat-activated self-healing topcoat. Minor scratches and swirl marks vanish from the surface when heat is applied, leaving your film looking flawless. The PPF’s low surface energy actively repels dirt, guaranteeing easy cleaning and effortless maintenance of your vehicle’s appearance.

Not only does our paint protection film offer unmatched defense, but it also preserves the resale value of your vehicle. By safeguarding your car’s original paint, you can avoid the need for costly touch-ups and repaints, ensuring your investment remains in top condition.

Whether you’re an auto enthusiast or a conscientious car owner, the 7.0mil Chameleon Black Red Paint Protection Film from Phenix is a wise choice that offers long-term benefits. Don’t compromise on quality, choose Phenix to give your vehicle the protection it truly deserves.

Features and Specifications

- Premium Quality Film: Crafted from top-notch materials.

- Durable and Long-Lasting: Built to withstand the test of time.

- Scratch and Stain Resistant: Offers robust protection against blemishes.

- High Endurance with Self-Healing Topcoat: Ensures lasting resilience and effortless repair of minor imperfections.

- Transparent with Superior Clarity: Free from the unsightly “orange peel effect.”

- Hassle-Free Installation and Removal: Easy to apply and take off.

- Resistant to Yellowing and Cracking: Maintains its pristine appearance.

- Size: 5ft x 49.21ft (1.52x15m)

- Chameleon Black Red Finish: This PPF variant imparts a distinctive and refined aesthetic to your vehicle.

- Packaging: Securely rolled in a sturdy box.

- Shelf Life: 2 years from the date of purchase when stored at 50°F to 80°F (15°C – 25°C) and 45% to 50% relative humidity.

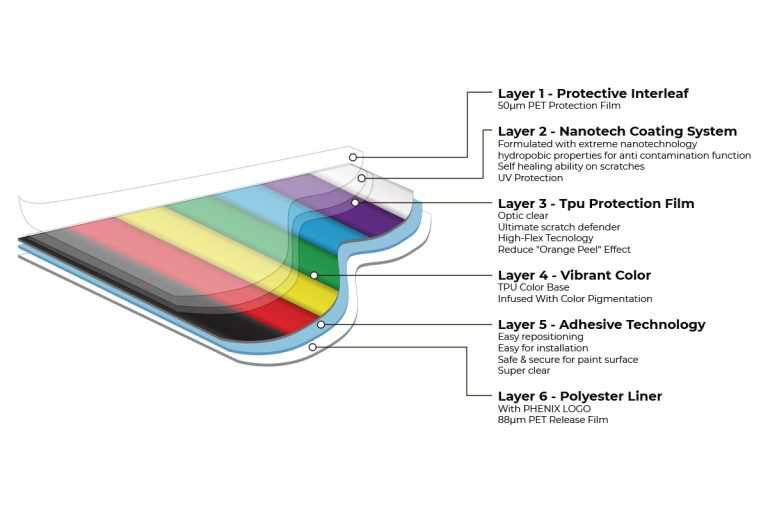

Product Structure

Prduct Specifications

Classification | Unit | Spec | Remark | |

Thickness | Ptotective Interleaf | µm | 50±2% | PET Protection Film |

Nanotech Coating System | µm | 6.5±2% | Self healing ability on scratches | |

TPU Protection Film | µm | 100±2% | Ultimate scratch defender | |

Vibrant Color | µm | 48±2% | Infused With Color Pigmentation | |

Acrylic Adhesive | µm | 25±2% | Easy repositioning | |

Release liner | µm | 75±2% | Satin Semi-transparent | |

Width | mm | 1520±0. 01% | 5ft | |

Length | mm | 15000±1% | 49.21ft | |

Adhesive appearance | – | Clear | – | |

Product Performance

Features | Test Method | Results |

Release force N/25mm | paste on steel board, 90° 26℃ and 60%, GB2792 | 0.27 |

Initial tack N/25mm | under 26℃ and 64%, GB31125-2014 | 9.5 |

Peel Adhesion N/25mm | paste on steel board, 180° 15 Minutes under 29℃ and 55%, GB/T2792-1998 | 9.35 |

Holding power(h) | paste on steel board, hang on by 25mm*25mm*1kg weight under 29℃ and 55%, GB/T4851-1998 | >75 |

Gloss(60°) | GB 8807 | ≥90(%) |

Application temperature | / | +20℃ to +25℃ |

Service Temperature | / | +20℃ to +80℃ |

Humidity Resistance | 120 hours exposure | No Detrimental Effect |

Salt spray Resistance | 120 hours exposure | No Detrimental Effect |

Water Resistance | 120 hours exposure | No Detrimental Effect |

Chemical Resistance | 1-hour diesel oil immersion, 4 hours antifreeze immersion | No Detrimental Effect |

Aging Test 1 | 7 days under 70°C | No adhesive residue with heat |

Aging Test 2 | 10 days under 90°C | No adhesive residue without heat |

Elongation at Break | GB/T 1040 | ≥400 |

Tensile Strength | GB/T 1040 | ≥20 (Mpa) |

Elongation at Break of Self-healing Coat | GB/T 1040 | ≥85 |

Application Method | Wet only | / |

Time Limits | Must use it within 3 Months after you receive the wrap film | 3 Months |

Storage Period

2 Years from the Manufactured Date in Temperature Range of 68 F – 78 F (20 C – 26 C) Relative Humidity 50%, Indoor Storage.

Installation Guidelines

- Clean the vehicle thoroughly.

- Cut PPF sections with extra for trimming.

- Spray soapy water on the surface.

- Apply PPF, float on soapy water.

- Squeegee out air and water, starting from the center.

- Heat and stretch the film to conform.

- Trim excess film with precision.

- Repeat the process for each section.

Please remove the protective cap prior to installation.

Key Information to Note

- Screen Display: Please be aware that the screen’s images, colors, and finishes are approximate. For precise product representation, always refer to the color swatch.

- Consistency in Production: When undertaking a wrapping project, it is advisable to use rolls from the same production LOT number, as there may be slight batch-to-batch variations in color.

- Surface Vulnerability: The film may be susceptible to scratching during application or daily usage. It is important to note that the warranty does not cover any scratching of the film

How Much Wrap Do I Need?

- Motorcycles: 3-5 meters (10-16 feet)

- Mini and Small Cars: 13-14 meters (42-45 feet)

- Convertibles: 15-16 meters (49-52 feet)

- Coupes: 17-18 meters (55-59 feet)

- Sedans: 17-18 meters (55-59 feet)

- Hatchbacks: 16-17 meters (52-55 feet)

- Sports Cars: 16-17 meters (52-55 feet)

- Station Wagons: 18-20 meters (59-65 feet)

- Sport-Utility Vehicles (SUVs): 17-19 meters (55-63 feet)

- Minivans: 20-24 meters (65-80 feet)

- Pickup Trucks: 22-28 meters (72-92 feet)

To ensure you have sufficient material for potential repairs, it’s advisable to add an extra 2-3 meters (6-9 feet) to your measurements. This precaution will help you avoid unexpected shipping expenses and delays.

To attain a flawless installation, here are some additional tips

- Maintain a clean and dust-free workspace to prevent imperfections.

- Check for any surface imperfections or damage before starting the installation.

- Use appropriate cutting tools to trim excess material for precise edges and corners.

- Ensure the film is applied smoothly, without wrinkles or bubbles.

- During stretching, be mindful of the film’s limits to avoid overstretching.

- Pay special attention to corners and edges, making sure they are securely adhered.

- For complex curves or contours, use a heat gun or heat source to aid in molding the film.

- Periodically inspect and maintain the installed film to ensure long-lasting quality.

Following these additional guidelines will help you achieve the best possible finish and ensure the longevity of the installed PPF.

Important Notice

The information regarding the physical and chemical characteristics presented in this document is derived from tests we consider reliable, but it should not be regarded as a warranty. This data is provided solely for informational purposes and is not accompanied by any guarantee or warranty. Prior to usage, purchasers should conduct an independent assessment to ascertain the suitability of this material for their specific requirements. Please be aware that all technical data may be subject to revisions. In the event of any discrepancies or variations between the English and foreign language versions of this document, the English version takes precedence.

Warranty, Limited Remedy, and Disclaimer

Unless an additional warranty is explicitly indicated on the relevant Phenix product packaging or product documentation, Phenix guarantees that each Phenix product complies with the applicable Phenix product specifications at the time of shipment.

PHENIX DOES NOT PROVIDE ANY OTHER WARRANTIES OR CONDITIONS, WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A SPECIFIC PURPOSE, OR ANY IMPLIED WARRANTY OR CONDITION ARISING FROM THE COURSE OF DEALING, INDUSTRY PRACTICES, OR TRADE USAGE.

In the event that a Phenix product does not meet this warranty, the sole and exclusive remedy, as determined by Phenix, is either the replacement of the Phenix product or a refund of the purchase price.